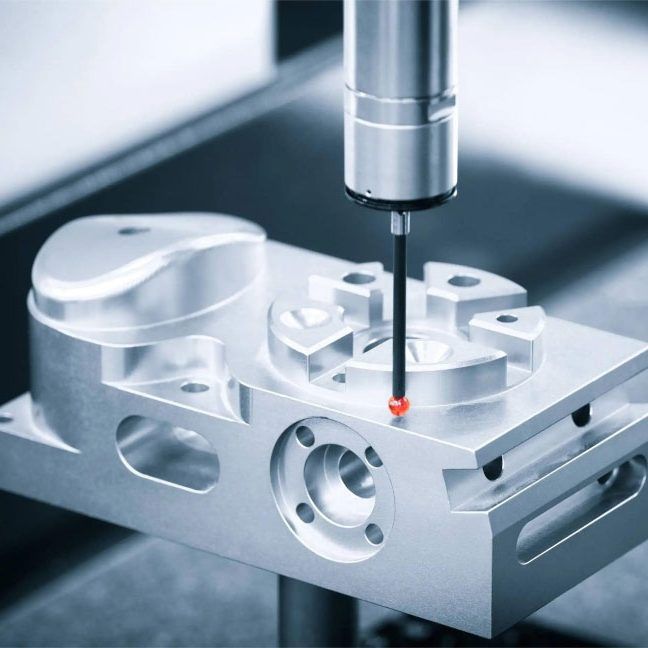

Modern manufacturing requires more than just machines—it requires certified processes, skilled engineers, and controlled production environments. Certified CNC machining capabilities ensure that complex parts can be produced accurately, efficiently, and repeatedly.

CNC Milling and Turning

CNC milling and turning form the foundation of precision machining. These processes allow manufacturers to create complex shapes, tight tolerances, and smooth surface finishes. Certification ensures these operations follow standardized workflows and inspection methods.

Multi-Axis Machining Compliance

Multi-axis machining (3-axis, 4-axis, and 5-axis) enables the production of highly complex components with fewer setups. Certified processes ensure accuracy across multiple axes and reduce the risk of dimensional errors.

Special Machining Processes

Advanced applications often require special machining methods such as EDM, laser cutting, and precision grinding. Certified manufacturers follow strict guidelines to control these processes, ensuring safety, accuracy, and repeatability.

Supporting Prototypes and Production

Certified CNC capabilities support both rapid prototyping and large-scale production. Standardized processes allow manufacturers to scale production without compromising quality or performance.

The Value of Certified Capabilities

Certification demonstrates technical competence, process control, and a commitment to quality. For customers, this means dependable parts, reduced lead times, and confidence in every order.